How an Optical Fibre Diameter Analyser Ensures Consistent Results in Fibre Optic Testing

Wiki Article

Exactly How an Optical Fibre Diameter Analyser Boosts Top Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a significant advancement in top quality control methodologies. By supplying real-time, exact measurements of Fibre sizes, this modern technology addresses the important requirement for consistency in manufacturing criteria.

Value of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is crucial in the field of optical Fibre modern technology, as it directly influences the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capability, depletion, and total transmission efficiency. Accuracy in gauging Fibre Diameter makes sure that the optical homes are kept within defined tolerances, which is essential for optimum signal stability.Variations in Fibre Diameter can cause raised losses as a result of scattering and modal diffusion, affecting the high quality of data transmission. In high-speed interaction systems, such discrepancies can cause substantial degradation of signal high quality, causing information errors and lowered performance. Additionally, regular Fibre Diameter is necessary for compatibility with ports and splicing innovations, which are integral components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily count on exact Diameter measurements to make certain compliance with sector requirements. By executing robust measurement strategies, producers can improve product reliability, decrease waste, and enhance overall system efficiency. Hence, the importance of Fibre Diameter measurement can not be overemphasized, as it serves as a cornerstone in the improvement of optical Fibre technology and its applications in modern interaction networks.

How the Analyser Functions

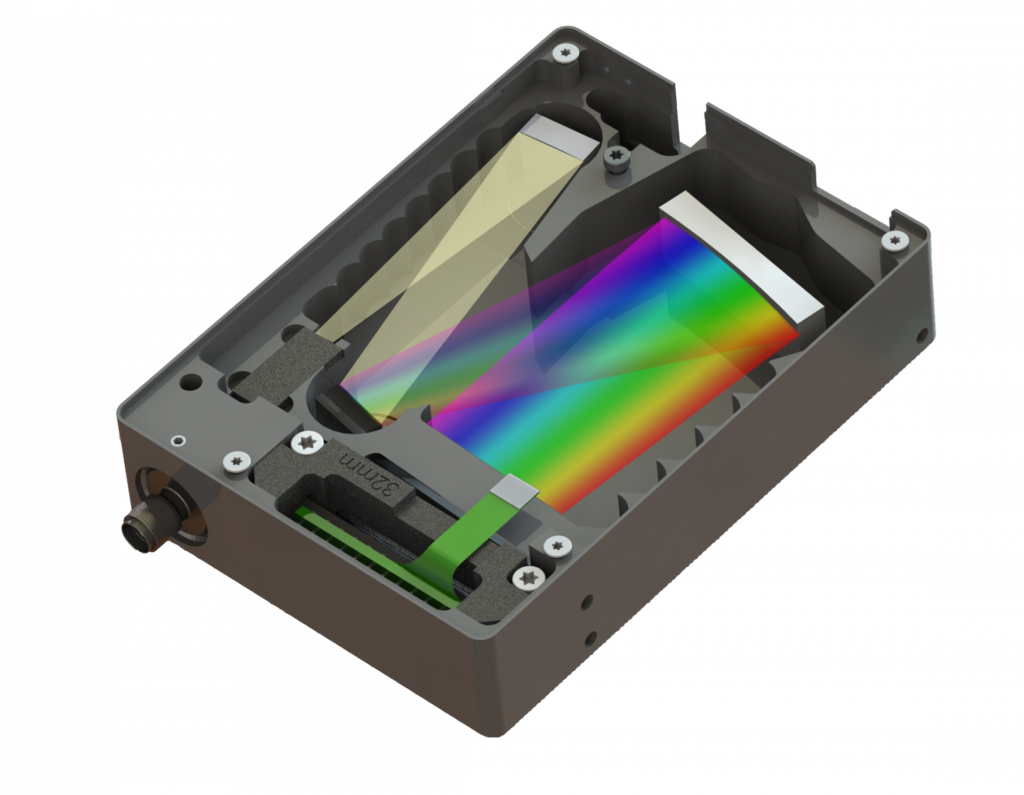

The effective measurement of Fibre Diameter depends on sophisticated analytical methods that make sure precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and progressed image handling algorithms to precisely analyze the Diameter of fibres as they are generatedOriginally, a laser beam of light is routed at the relocating Fibre, producing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution cameras placed tactically along the production line. The recorded photos are after that processed in real-time to identify the Fibre's Diameter with exceptional accuracy.

The system makes use of innovative algorithms that represent numerous aspects, consisting of variations in light intensity and ecological conditions, to enhance dimension dependability. It can detect minute changes in Diameter, such as changes that could take place during the manufacturing procedure.

Furthermore, the analyser is qualified of managing multiple fibres at the same time, raising throughput without endangering precision. By giving instantaneous comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial function in keeping rigorous quality control standards, making certain that the end product satisfies sector specs and client needs.

Advantages of Real-Time Monitoring

While traditional techniques of keeping an eye on Fibre Diameter typically entail time-consuming post-production checks, real-time tracking significantly improves the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive strategy permits producers to identify variances in Fibre Diameter try this as they take place, rather than waiting until manufacturing is total to evaluate high qualityBy constantly measuring the Diameter throughout manufacturing, producers can make sure that the fibers satisfy stringent specs, causing minimized variability and improved consistency. browse around this site Real-time tracking also allows prompt restorative activities to be taken, minimizing waste and preventing malfunctioning fibers from getting in the supply chain.

In addition, this technology assists in boosted information collection and analysis, offering insights into manufacturing trends and potential areas for renovation. Such data-driven decision-making empowers makers to maximize processes and keep high standards of quality assurance.

On top of that, real-time surveillance fosters a culture of constant renovation within the production setting. Employees are more engaged when they can see the effect of their operate in real-time, bring about increased accountability and a commitment to quality. On the whole, the execution of real-time tracking systems in optical Fibre production translates to superior item quality and raised client fulfillment.

Impact on Manufacturing Performance

Implementing optical Fibre Diameter analysers significantly boosts production effectiveness by simplifying the production procedure. These gadgets assist in constant monitoring of Fibre Diameter, allowing makers to detect variances in real-time. By recognizing incongruities immediately, assembly line can be adjusted swiftly, minimizing downtime and minimizing the possibility of producing faulty products.Moreover, the integration of these analysers right into the production process makes it possible for better source allowance. With exact Diameter dimensions, drivers can enhance product usage, ensuring that resources are not lost on problematic fibers. This precision additionally contributes to much less scrap and remodel, ultimately lowering production expenses.

The automation provided by optical Fibre Diameter analysers decreases dependence on hand-operated assessments, which are often taxing and susceptible to human error. Because of this, employees can concentrate on even more strategic jobs, boosting total efficiency.

Furthermore, the data generated from these analysers can educate procedure renovations and help with much better decision-making. By analyzing trends in Fibre Diameter variants, makers can apply positive measures to improve production methods and preserve consistent high quality. In summary, optical Fibre Diameter analysers play an essential role in boosting production efficiency, resulting in better output and increased success.

Study and Success Stories

Across various fields, study highlight the transformative effect of optical Fibre Diameter analysers on production processes. One popular instance is a leading telecoms company that faced obstacles with inconsistent Fibre sizes, leading to increased being rejected prices. By integrating This Site an optical Fibre Diameter analyser, the firm accomplished real-time tracking of Fibre measurements, leading to a 30% decrease in problems and significant expense financial savings.

In addition, a research organization concentrating on sophisticated materials utilized optical Fibre Diameter analysers to improve their speculative processes. The analyser's capability to offer comprehensive understandings right into Fibre consistency made it possible for the growth of innovative products with better efficiency features.

These success tales underscore the essential function of optical Fibre Diameter analysers in improving quality assurance, improving production efficiency, and driving technology throughout diverse industries.

Final Thought

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in improving top quality control within Fibre production. As demonstrated through different situation research studies, the analyser verifies important for achieving exceptional item high quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers enabled for stringent top quality control, guaranteeing that the generated fibres fulfilled exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays an essential role in boosting quality control within Fibre manufacturing.

Report this wiki page